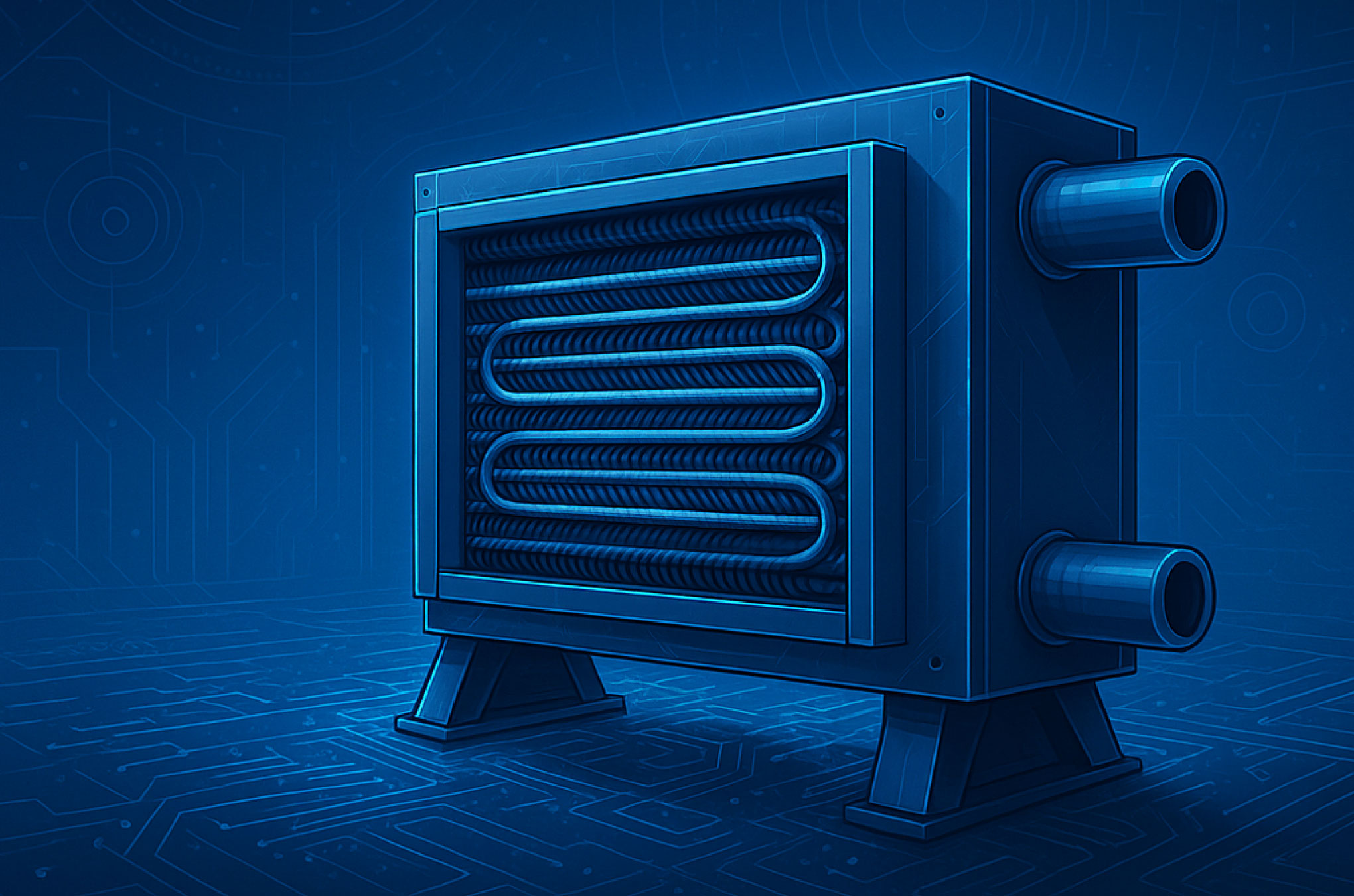

A new generation of direct-expansion (DX) ammonia evaporators (R717/NH₃) designed with a nested circuit specifically conceived to optimise the defrost process.

This technological breakthrough meets the growing demand for more efficient, safer and more sustainable solutions in industrial refrigeration, delivering significant improvements in performance and operability.

Our commitment to innovation and sustainability drives us to develop solutions that align with new market requirements and environmental regulations. The gradual restriction on fluorinated refrigerants has accelerated the adoption of natural alternatives such as ammonia (NH₃), prompting continuous evolution in industrial refrigeration system design.

Against this backdrop, we are developing, within our industrial range, DX evaporators for NH₃ refrigeration in low-charge systems. These systems use roughly 30 times less refrigerant than a flooded system, minimising risk in the event of a leak by reducing the total quantity of ammonia on site.

From an operational standpoint, this reduced charge demands meticulous design to ensure thermal efficiency and system reliability. Defrost management is critical in these evaporators, which is why we offer several technical solutions—the most recommended being the nested coil, allowing residual system heat to be harnessed for defrosting with hot gas or glycol.

This strategy not only contributes to efficient system operation but also forms part of a comprehensive approach to energy optimisation and reduced environmental impact.

In short, designing low-charge NH₃ industrial refrigeration systems requires balancing performance, safety and sustainability. At GARCÍA CÁMARA we are ready to provide technical solutions that meet these challenges with proven effectiveness.