Frost formation on evaporator coils is one of the most common and challenging issues in refrigeration systems. When ice accumulates on heat exchange surfaces, such as tubes and fins, it creates a layer that acts as a barrier, significantly reducing heat transfer between the refrigerant and the medium to be cooled. This not only decreases system efficiency, but can also lead to increased energy consumption and affect cooling capacity. That is why having effective defrosting solutions—such as the nested circuit system—is essential to maintain optimal performance and efficiency in refrigeration systems.

Several methods can be used to remove this frost, such as:

- Air defrost: This is a simple technique that involves temporarily stopping the flow of refrigerant through the evaporator coils while keeping the fans running. By doing so, the warm air generated by the fans helps melt the frost through frictional heat and heat transfer from the air to the frozen surface. This method is especially useful when the ambient temperature is above 5°C, as under these conditions the warm air can defrost the frost without the need for more complex or costly systems.

- Electric resistance defrost: This is a straightforward and direct method for removing frost from coils. It involves suspending the flow of refrigerant through the tubes and activating electric heaters placed between the tubes and fins. Thanks to the Joule effect, these resistances generate heat that melts the accumulated frost. However, it’s important to note that this system requires additional electrical consumption, as the heaters need power to generate heat. It is an effective solution, particularly in situations that require fast and controlled defrosting, though it does imply extra energy costs.

- Hot gas defrost: This method works by introducing hot or warm gas—taken from the discharge gases of the refrigeration system—directly into the interior of the evaporator tubes. Since the hot gas has a higher temperature than the frost covering the tubes and fins, it helps melt the frost quickly. However, this method requires that hot gas be available for the process, and it also involves considering the distance between the compressor unit (where the hot gas is generated) and the evaporators. As the gas travels through the system, it loses temperature, which may reduce its effectiveness in defrosting. It is an efficient method, but proper planning is necessary to ensure the gas reaches the coils at a sufficient temperature

DEFROST BY INTERLEAVED COIL – Versatile Technology

At García Cámara S.L., we integrate technology and innovation to care for the planet. That’s why we are committed to defrosting systems that harness heat recovery as an energy source—an efficient and environmentally friendly solution.

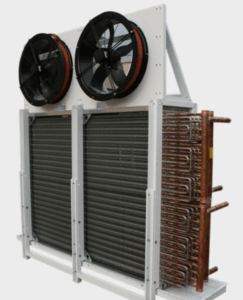

Our interleaved coil system stands out for its high effectiveness, simplicity, and low operating cost. It keeps evaporators free of frost without consuming additional electricity, resulting in a lower energy impact.

Thanks to its rapid action, evaporators regain their optimal performance in a very short time, which is especially useful in demanding applications such as low-temperature cold rooms, freezing tunnels, or blast chillers.

Moreover, its versatile design allows integration with any type of refrigerant, as it operates without circulating through the same coil.

In short, we are committed to smart solutions that combine efficiency, sustainability, and technology—serving both our clients and the planet.

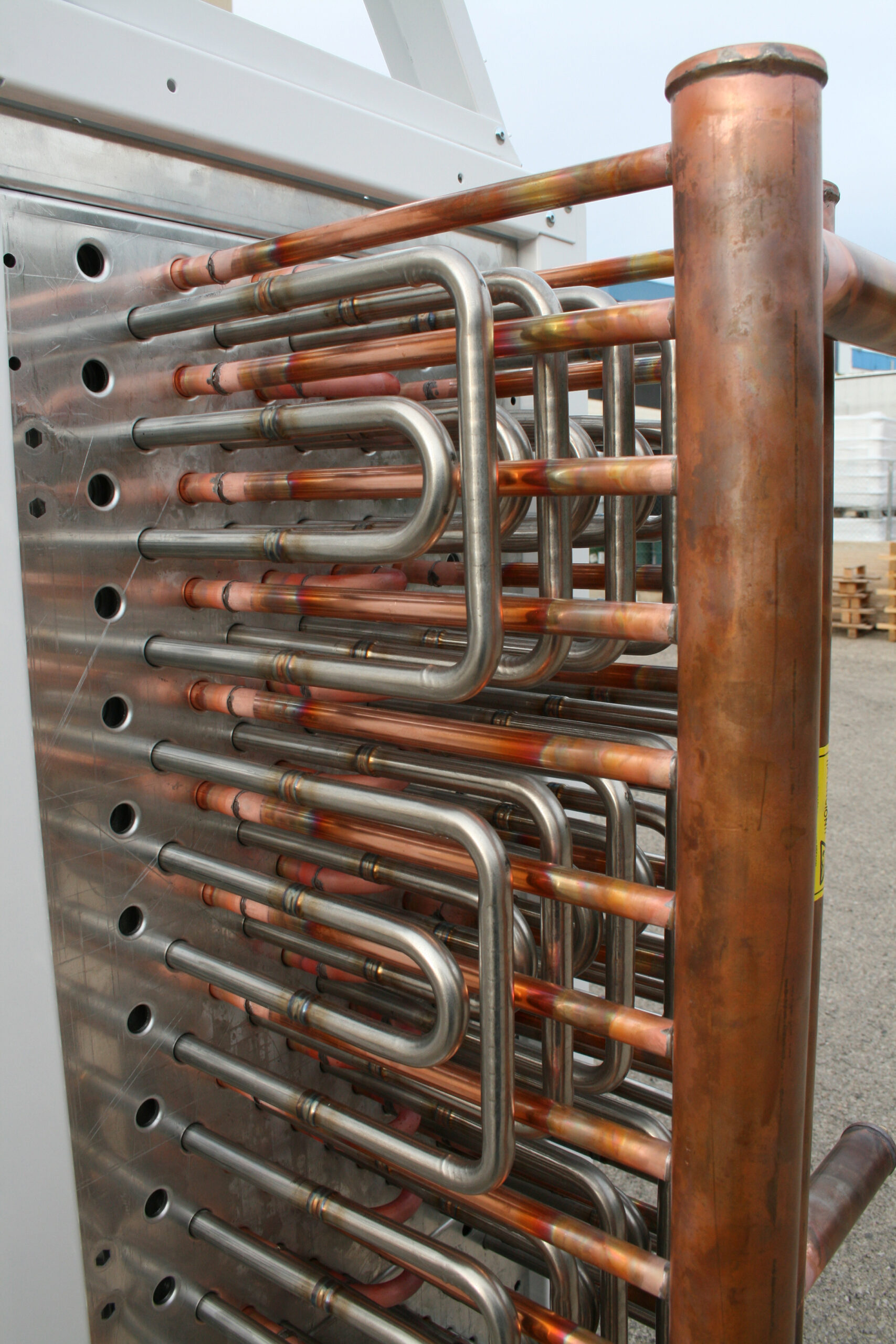

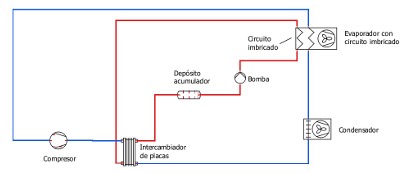

- Defrost by interleaved coil: This system consists of a secondary circuit through which a heat transfer fluid is circulated. In this setup, the evaporators are equipped with two interleaved (overlapping) coils—one carrying the refrigerant (cold coil) and the other carrying the higher-temperature heat transfer fluid (hot coil).

Thanks to the heat recovery from the compressor’s discharge gases and the use of a heat exchanger, the heat transfer fluid is heated and can be stored in a tank. This allows heat to be readily available at the start of defrost cycles without the need to generate hot gas instantly, optimizing the process and reducing energy consumption. It is a highly intelligent system that makes use of residual heat from the refrigeration system to improve overall efficiency.

García Cámara is efficiency and sustainability.